Corrosion Protection: Sustainable Solutions for Metals

Corrosion is one of the biggest enemies of metals in numerous industries. EPG AG offers innovative surface coatings that not only provide excellent corrosion protection but also additional properties such as chemical resistance and abrasion protection. With their products Nanoseal® and Saphiral®, EPG AG sets new standards in surface technology.

Corrosion Protection for Stainless Steel and Titanium with Nanoseal®

The demand for high-quality surface finishes with corrosion protection is high worldwide, especially in the automotive industry. EPG AG provides tailored solutions for exterior components that not only prevent corrosion but are also resistant to chemical attacks and mechanical abrasion.

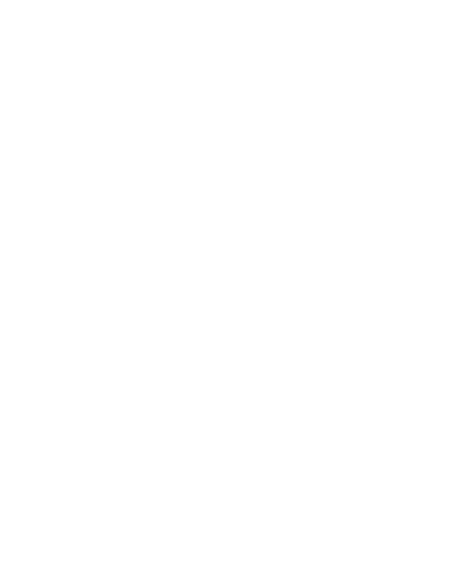

Nanoseal® is a glass-like protective coating that achieves excellent results on metals such as stainless steel and titanium. The main characteristics:

Application Areas of Nanoseal®:

Corrosion Protection for Aluminum with Saphiral®

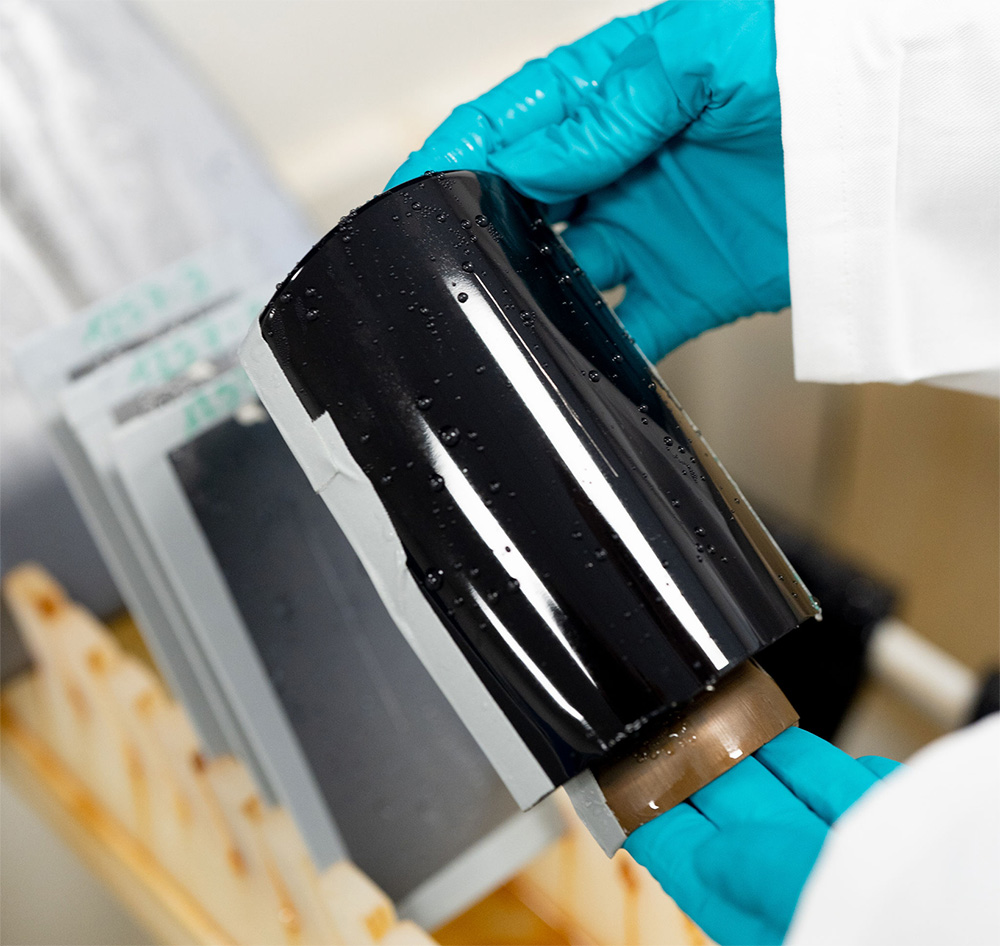

Aluminum is popular due to its light and aesthetic properties but is susceptible to corrosion, abrasion, and scratches. With Saphiral®, EPG AG offers a state-of-the-art solution that eliminates these disadvantages while preserving the natural appearance of the metal.

Properties of Saphiral®:

Application Areas of Saphiral®:

Automotive Industry

Design and Architecture Industry

Household Appliances

Aviation Industry

Sustainability and Future Prospects

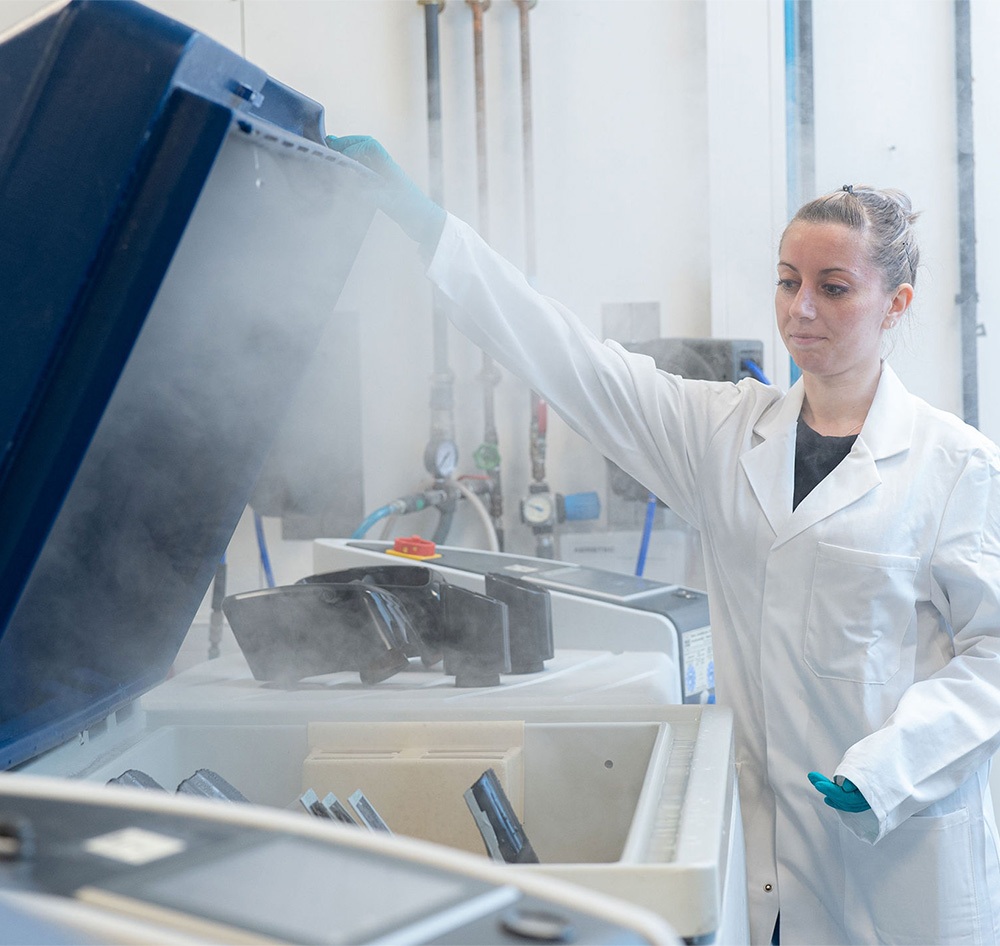

All coatings from EPG AG are environmentally friendly and comply with the REACH regulation, which regulates the use of hazardous substances in the industry. This makes EPG's solutions particularly attractive to companies that value sustainability and legal compliance.

With Nanoseal® and Saphiral®, EPG AG offers versatile and highly functional alternatives to traditional coating processes such as chrome plating and anodizing. The products combine elegant appearance, corrosion protection, and environmental protection, making them ideal for the challenges of modern industries.