Topcoat or Anodizing Replacement with Saphiral®: Innovative Coating Solutions

Aluminum surfaces are often subjected to anodizing processes to protect them from corrosion, mechanical influences, and chemical stresses, or to give them a desired coloration. However, the classic anodizing process also brings challenges, especially with certain alloys and manufacturing processes.

The Alternative to Anodizing for Uniform and Resistant Aluminum Surfaces

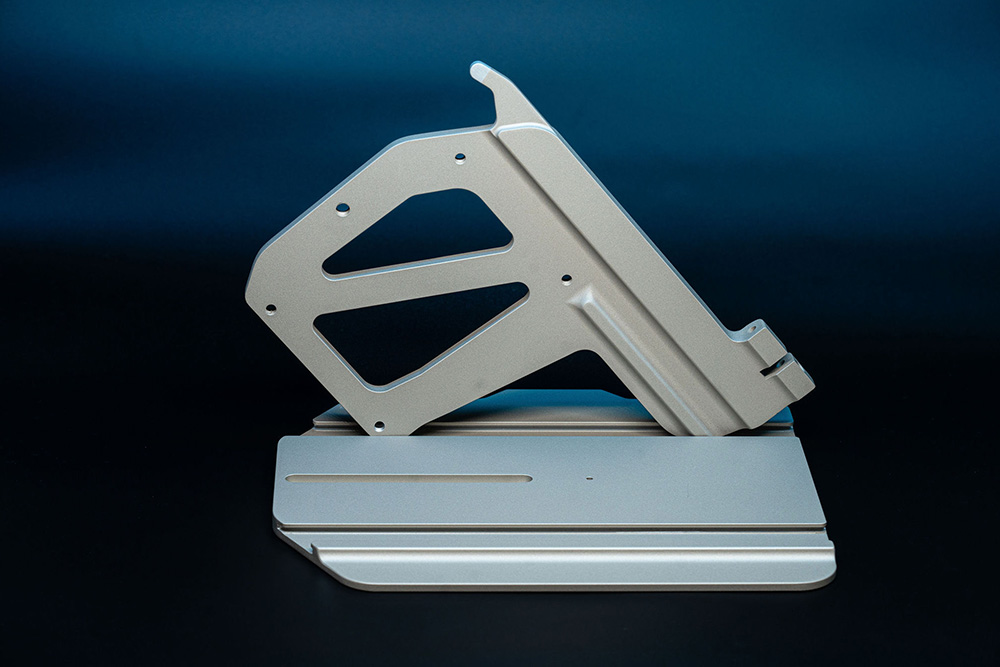

Many aluminum alloys show an uneven appearance with undesired discolorations after anodizing. Moreover, optical anodizing is often not feasible with cost-effective die-casting processes, which limits the application possibilities of aluminum parts. Therefore, there is an increasing demand for alternative coating solutions that are suitable for almost all alloys and manufacturing processes while ensuring a uniform appearance.

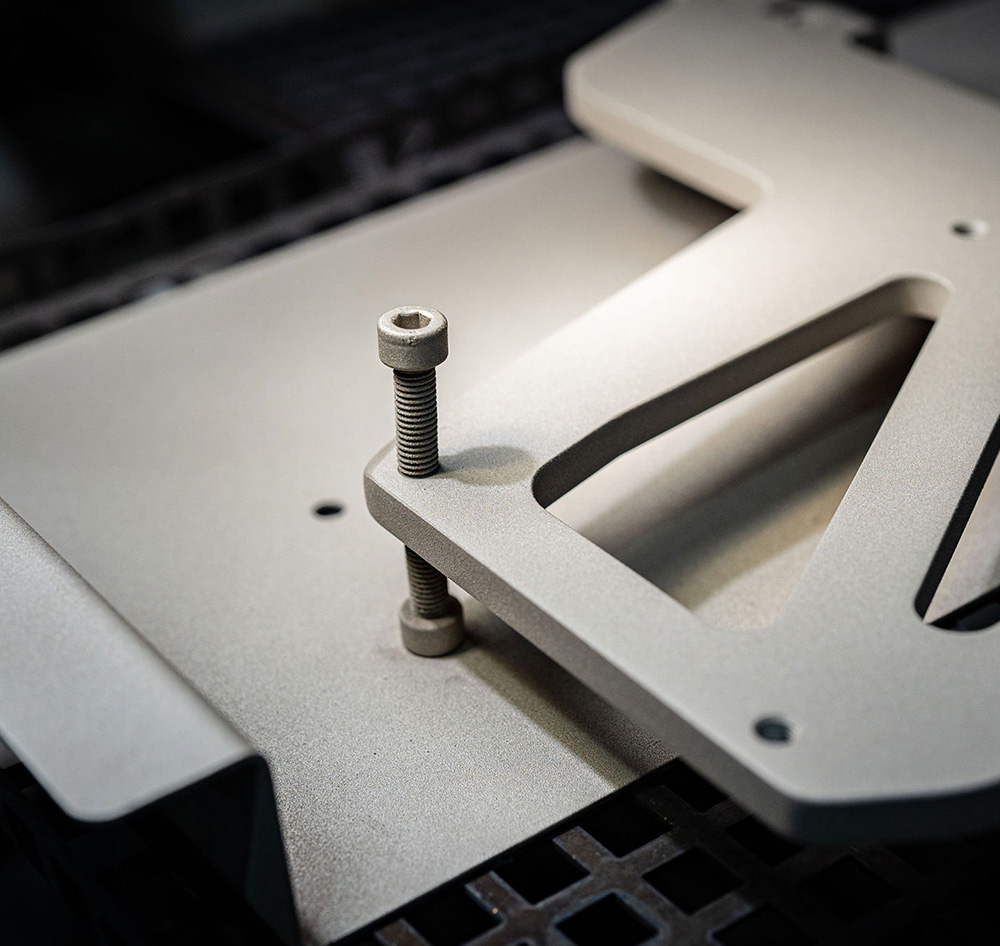

EPG AG has developed a solution that meets these requirements with its innovative Saphiral® coating system. Saphiral® has proven particularly successful in the aviation industry, as it enables uniform and color-adaptable surface finishing while offering high scratch resistance and chemical stability.

Saphiral® – Perfect Surface Protection for Aluminum

One of the biggest advantages of Saphiral® is its flexibility in color design. While color options are limited and color baths are costly in the classic anodizing process, Saphiral® allows for easy adaptation of coloration to individual customer requirements. Smaller batch sizes or specific color shades are easily achievable, and once developed, colors can be reproduced at any time.

Properties of Saphiral®:

Applications of Saphiral®

Saphiral® opens up versatile applications in various industries:

Aviation Industry

Automotive Industry

Design Industry

Household Appliances

Why Saphiral®?

The sol-gel coating with Saphiral® offers a forward-looking alternative to conventional anodizing processes. The elimination of chemically intensive processes such as anodizing makes the process more environmentally friendly and efficient. REACH compliance further underlines the focus on sustainability.

With Saphiral®, you combine surface finishing, corrosion protection, and functionality in a single coating system that can be individually adapted and meets the highest requirements.

With Nanoseal® and Saphiral®, EPG AG offers versatile and highly functional alternatives to traditional coating processes such as chrome plating and anodizing. The products combine elegant appearance, corrosion protection, and environmental protection, making them ideal for the challenges of modern industries.