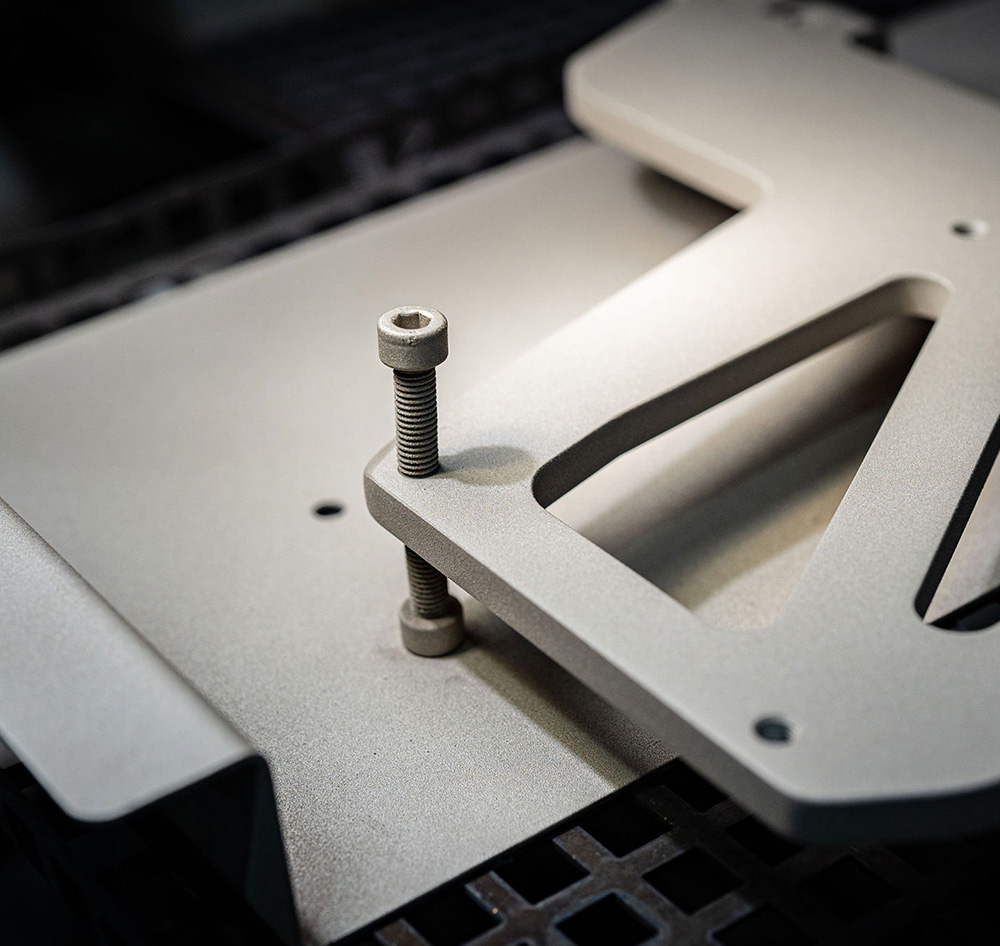

Surface Coating for Aluminum in the Aviation Industry

Maximum Durability and Perfect Aesthetics for Aluminum Components in Aircraft Cabins

EPG AG offers an innovative sol-gel coating, Saphiral®, as a powerful solution for aluminum components in aviation. This surface technology significantly increases resistance to corrosion, abrasion, and chemical influences while creating homogeneous and visually first-class surfaces.

Challenges in Aluminum Refinement

Aluminum is the preferred material in the aviation industry due to its low weight and high stability. However, aluminum alloys often contain elements such as magnesium, silicon, copper, and zinc, which make the material susceptible to corrosion and optical irregularities. Until now, the anodizing process (Eloxal) was frequently used, but it has clear disadvantages:

The Powerful Alternative to the Anodizing Process

Our sol-gel-based surface coating Saphiral® offers a convincing alternative to conventional anodizing and ensures permanently homogeneous and high-quality aluminum surfaces.

Advantages of Saphiral®:

High-precision and Modern Coating Process

Our sol-gel coating is customized to meet customer requirements and applied in a precise, computer-controlled process: Saphiral® also scores in contact with food. The coating meets environmental and health standards and ensures sustainable material protection.

Your Advantage with Saphiral®